This machine produces the curb by wet press method. The mechanism of the machine in the three-station model is such that the required mortar is prepared by the batching system and poured into the hopper of the machine. Before injecting the mortar into the mold, the operator should place the bottom filter in the mold, and after the injection of the mortar, the upper filter should be placed on the mortar by a side device or by another operator. At the same time as the pressure process, the water suction device, excess water from the drawn mortar and production curb is almost free of water. At the end of the pressure and rotation of the table, the process of emptying the mold is done. Then the product harvesting device connected to the production line removes the produced wet press table from the device The harvesting processe of this machine are fully automatic. The pallets that the lift truck driver has placed in the machine warehouse are automatically placed on the rolling and then the produced curb is placed on the pallet. When the capacity of the pallet is full, the pallet moves on the Roller conveyor and after the Roller conveyor stops, the lift truck driver transfers the pallet to the steam room.The permanent filter can replace the disposable filters of the mold top layer. Permanent filters are suitable for approximately 100-150 production units. The time to change the permanent filter is about 5 minutes.This device is designed in such a way that it has the ability to support different sizes of molds.

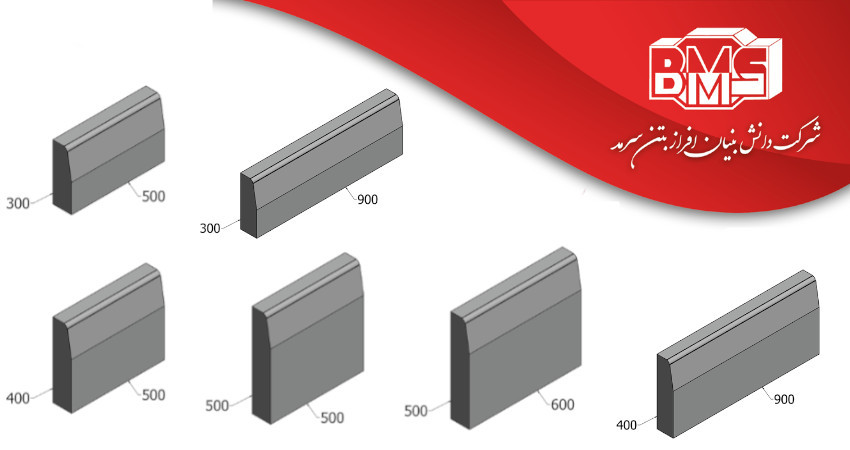

Molds that can be installed on the device:

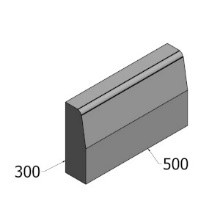

- 30×50

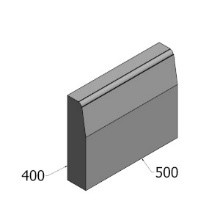

- 40×50

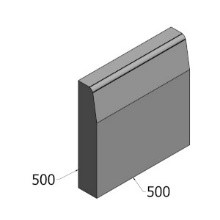

- 50×50

- 50×60

- 30×90

- 40×90

The system of this device is designed in such a way that it is possible to apply changes based on the customer's choice on the dimensions of the production table

Specifications of consumable parts for three-station wet press curb production line devices

- The material of the steel sheets used in the machine is ST37, and the parts exposed to corrosion are made of CK45 hardened sheet.

- The control panel of this machine is set and installed on the device in two ways: fully automatic (PLC) and manual system for use in emergency situations.

- The shafts used in the jacks are made of Italian hard chrome steel

- This machine is designed and built in such a way that it is suitable for working in different geographical environments and working in different conditions.

- The piston tubes of the jacks are of Turkish or Italian type.

- The control valves of the machine are DUPLOMATIC type from Italy.

- All pumps used in the machine are of Iranian type (due to easy access to after-sales services and spare parts).

- All electric motors used in the machine are from China (can be changed based on customer order).

- All sensors are Korean HANYOUNG or AUTONICS.

- Electrical panel and panel supplies are from Korea's LS.

- The control and industrial automation system of the device is by PLC and from the Korean brand FATEK or DELTA (in case of customer order from SIEMENS, Germany).

Additional equipment in the three-station wet press curb production line

Specifications of the three-station wet press curb production line

In the following, we will check the specifications of the products produced by the wet press machine of three stations

| Curb dimension |

Number per station |

Production every eight hours |

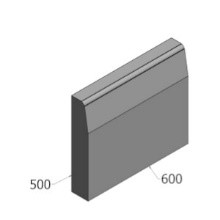

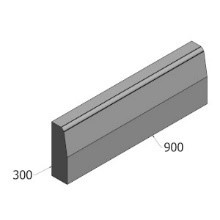

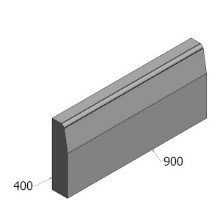

image |

| 30×50 |

One piece |

550-600 |

|

| 40×50 |

One piece |

550-600 |

|

| 50×50 |

One piece |

550-600 |

|

| 50×60 |

One piece |

550-600 |

|

| 30×90 |

One piece |

550-600 |

|

| 40×90 |

One piece |

550-600 |

|