The dragline batching plant device consists of two main components: a scraper and a steel wire rope about 13 meters long. These parts help guide construction materials into the device and enable material weighing. Using a loader with this device is inefficient, so fixed cranes mounted on the dragline batching plant are recommended to efficiently collect stored materials and improve performance. This feature necessitates a separate operator to control the scale and ensure the safety of people near the dragline. The dragline batching plant is one of the oldest devices for producing concrete, but due to frequent repairs, it is rarely used. With a capacity of 40 cubic meters, it can produce up to 120 cubic meters of concrete.

Wet Dragline Batching Plant

After the materials are loaded and transferred to the concrete mixer, mixing continues until the blend becomes uniform. Once loaded, they are directed into the mixer, where the mixing process occurs. The wet dragline batching plant is a widely used model and can be utilized in most construction projects.

Dry Dragline Batching Plant

In the dry dragline batching plant model, construction materials are weighed dry in specific proportions and then transferred to the truck mixer for blending. Due to the heterogeneity of the materials, this device is used in special projects.

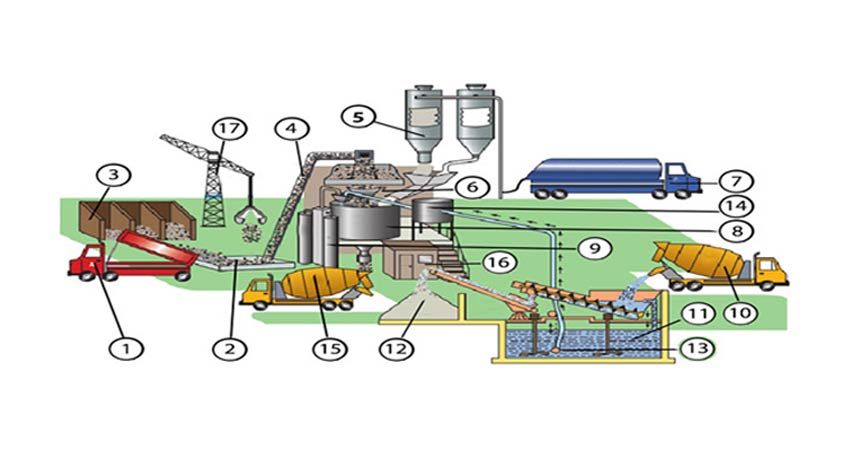

Components and Concrete Production Steps in the Dragline Batching Plant

1- Material Delivery

2- Aggregate Receiving Hopper

3- Storage Bin

4- Conveyor Belt

5- Cement Silo

6- Weighing Hopper

7- Cement Delivery

8- Mixer

9- Types of Concrete Additives

10- Water Supply Truck

11- Water or Recycled Water

12- Reclaimed Materials

13- Pump

14- Water Tank

15- Loaded Concrete in Ready-Mix Truck

16- Control Room

17- Dragline

Applications of Dragline Batching Plant

The dragline batching plant is used in large-scale construction and civil projects that require high daily volumes of concrete, reducing transportation costs from the factory. It's also widely used in projects with limited space and resource accessibility.

How the Dragline Batching Plant Works

Sand, gravel, and other materials are loaded via the wire rope (dragline) and scraper, then placed on a conveyor belt (or transfer bucket) for weighing. Cement stored in silos is measured using a hopper and added to the other materials. Water is then added accurately by volume or weight using a pump. After complete mixing, the combined materials are discharged through a hydraulic valve into the truck mixer positioned below the mixing bucket. All these stages can be monitored and adjusted from the control room.

Tips for Using a Dragline Batching Plant

- Avoid personnel movement around the dragline during operation.

- Do not overload the dragline beyond its defined capacity.

- Employ an experienced operator to handle the batching plant.

- Ensure the dragline system's grounding wire is properly connected.

- Regularly observe the cement transmission motor and gearbox. Replace gear oil on time to extend gearbox lifespan.

- Properly prepare the installation area with ground leveling, foundation creation, and secure the base using bolts and welding.

- Never open the mixer lid while materials are mixing.

- If the screw conveyor becomes blocked during cement transfer, use a rubber mallet to clear the blockage.