Semi-Automatic 6-Mold Silo Block-Making Machine BT 4500

This model of block-making machine is capable of producing various types of blocks using different materials such as pumice, perlite, LECA, washed sand, and crushed sand. Its production system is designed as mobile (egg-laying), enabling fast and efficient block production.

Key Specifications:

- Equipped with a silo with a capacity of 0.8 cubic meters for storing raw materials

- Hydraulic mold filler to facilitate the feeding process

- Equipped with two powerful vibration units with 2-horsepower electric motors and 3000 RPM

- Ram (hammer) designed for both pressing and striking operations

- Capable of operating in semi-automatic and automatic modes with a PLC system

- Option to use a hydraulic lock for mold unloading in the automatic model

|

Specifications of Products Produced by the Semi-Automatic 6-Mold Silo Block-Making Machine BT 4500

|

|

Ceiling and wall (partition) blocks

|

|

Block Dimensions

|

Number per Cycle

|

Production in 8 Hours

|

|

40*20

|

6 Units

|

4000 Units

|

|

40*15

|

8 Units

|

6000 Units

|

|

50*15

|

8 Units

|

6000 Units

|

|

40*10

|

11 Units

|

8000 Units

|

|

50*10

|

11 Units

|

8000 Units

|

Specifications of Consumable Parts for the Semi-Automatic 6-Mold Silo Block-Making Machine BT 4500

This model, similar to the simple semi-automatic 6-mold block-making machine, is designed for various geographical conditions. The components and systems used in it include:

- Automatic Control: PLC from brands FATEK, DELTA, SIEMENS, Pars Fanal

- Motors: Chinese electric motors (customizable based on customer request)

- Sensors: Brands HANYOUNG, AUTONICS (in the automatic striking model)

- Solenoid Valve: Turkish brand (in the automatic striking model)

- Electrical Components: Panel and electrical board from LS Korea

- Hydraulic Hoses: Turkish brand (customizable)

- Automatic Lock: Locally produced, specific to the automatic striking model

- Hydraulic Pump: 22-liter European gear pump

- Hydraulic Valve: Hydropack (European)

- Body Material: ST37 steel with high strength

- Jack Shafts: Italian hard chrome steel

- Jack Tubes: Italian or Turkish product

- Oil-Based Vibration Unit: Locally produced with stable performance

Comparison with Similar Device

This device is competitive with the automatic block-making machine. It can also be compared with the tabletop ceiling model and the manual block-making machine. If you are looking to increase production speed and reduce operator dependency, the fixed automatic 12-mold block-making machine would be a better option.

What is a Semi-Automatic Block-Making Machine?

This model of block production equipment is used to manufacture various types of construction blocks and is available in different models based on production volume. One of the most commonly used options in this category is the semi-automatic models, which operate quickly but require operator intervention to complete the production process.

In automatic models, the production process is carried out using electric vibration, which increases production speed and block quality. Additionally, the leveling and pressing system in these models is hydraulic, which is why they are also classified as hydraulic machines.

Thanks to the vibration system, these machines can produce high-quality blocks. However, the production volume also depends on the operator’s performance, as raw materials are fed into the machine by the operator, and the production stages are controlled manually.

Types of Semi-Automatic Models

These machines are categorized based on the number of molds they use. Among the most common models in this group are the simple and silo-equipped hydraulic 6-mold models. The more molds a machine has, the higher the production capacity per cycle.

Additionally, some models are equipped with a silo for storing raw materials, which reduces the need for constant material handling. In this case, the semi-automatic silo-equipped 6 or 12-mold model is a suitable choice for optimizing the production process.

Applications of the Semi-Automatic Block-Making Machine

These machines, like other block production models, are used to manufacture various types of construction blocks. The only difference lies in the production speed; they are faster than manual models but slower than fully automatic ones.

With the use of these machines and operator assistance, it is possible to produce between 4000 to 4500 blocks per work shift. This amount is approximate and may vary based on various factors.

Advantages of Semi-Automatic Block Making

- Capability to produce various types of wall, ceiling, lightweight, partition, and cement blocks

- Reduced energy consumption compared to automatic models

- Increased efficiency compared to manual models

- Simple operation and ease of use by the operator

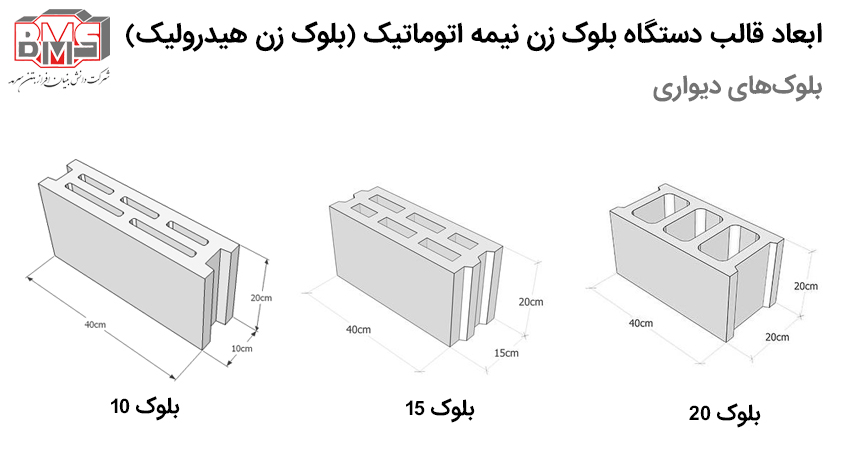

The mold dimensions of the semi-automatic block-making machine (also known as the hydraulic block-making machine) vary depending on the type of block to be produced and the machine model. However, these machines are designed to produce standard construction blocks, such as cement blocks, with precision and high quality. The mold dimensions used in the semi-automatic block-making machine are typically determined based on common standards for construction block production. These standards are designed to ensure the blocks’ usability in various construction projects and to guarantee their strength and durability. The molds are designed to produce blocks with various dimensions tailored to the needs of different construction projects. For example, molds used for cement block production have standard dimensions that meet the requirements of construction in different regions. These dimensions are chosen to ensure that the produced blocks not only meet size and shape standards but are also of high quality and durability.

Common mold dimensions for cement blocks in the semi-automatic block-making machine are as follows:

- Wall Block Molds:

- Block 10 (wall block with a width of 10 cm): 40x20x10 cm

- Block 15 (wall block with a width of 15 cm): 40x20x15 cm

- Block 20 (wall block with a width of 20 cm): 40x20x20 cm

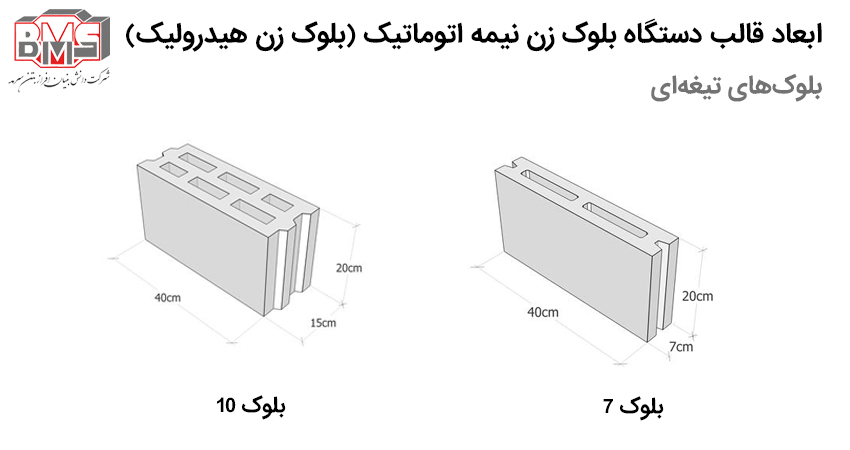

- Partition Block Molds:

- Block 7 (partition block with a width of 7 cm): 40x20x7 cm

- Block 10 (partition block with a width of 10 cm): 40x20x10 cm

- Special Molds:

Special molds for producing closed-bottom or hollow blocks, LECA blocks, and others are available, customized based on customer needs and production type.

Semi-automatic block-making machines are generally capable of producing blocks in various dimensions and shapes by changing the molds. Therefore, mold dimensions can be adjusted based on production needs and local standards.